What happens moistured filament used?

Almost 3D printing filament takes moisture from the atmosphere. It is well known moisture affects 3D printing, but little is known about what happens when filament is moistured. When moistured filament is used, three things occur mainly. (1) Foaming, (2) Resin melt chenge, and (3) Hydrolysis.

(1) Foaming

When moistured filament melt, water inside expands at once and becomes bubbles. Bubbles are generated in the highly viscous molten resin, it will not disappear after print immediately. As it is, it will be printed with bubbles mixed.

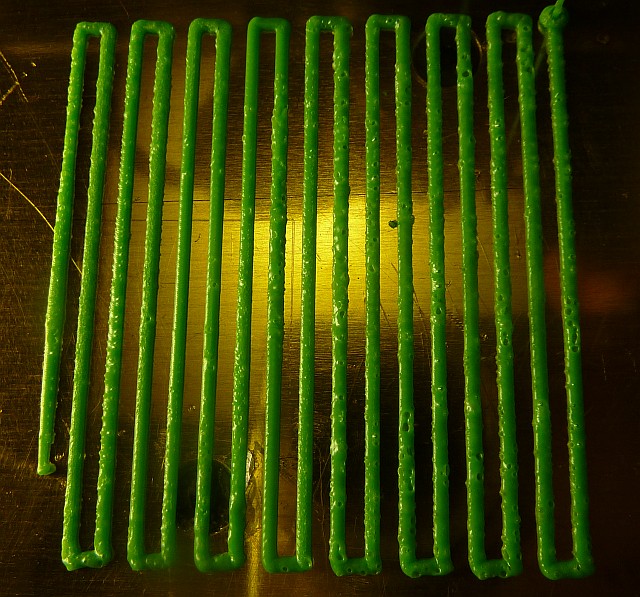

Bed adhesion decreases

Image is raft printed with a moistured filament. You can see many crater-shaped bubbles. These bubbles are generated not only on the surface that is visible, but also on the surface that is in contact with the bed. Therefore, even if it looks well contacted, if there are bubbles, the actual contact area will be reduced. Since the adhesion of the bed decreases, problems such as peeling and warping of the prints are likely to occur.

Damp filament - Source:solidoodletips.wordpress.com

Interlayer adhesion decreases

Bubbles are generated not only in the first layer but also upperlayer. Resin does not filled the area where bubbles are formed, so interlayer adhesion will be reduced. The appearance of the prints will also becomes worse.

Moisture in new printer filament - Source:thrinter.com

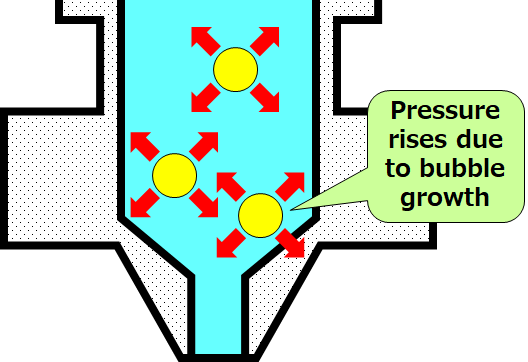

Nozzle clogging occurs

The pressure inside the nozzle and barrel rises as bubbles grow. This internal pressure acts in the direction that pushes back the filament and thus becomes a resistance. Since the internal pressure gradually increases with printing time, the dispense followability gradually deteriorates. When internal pressure reaches the limit, it will not be possible to dispense and the nozzle will be clogged.

If the filament cannot be loaded even if the nozzle is replaced and the motor makes a "Dan! Dan!" sound, there is a possibility that the internal pressure is too high.

In addition, when the internal pressure rises, extra force is required for extruding, which puts a load on each 3D printer component. Problems such as wear of drive gear, plastic parts breaks, and insufficient extruding are also likely to occur.

(2) Resin melt chenge

Resin becomes difficult to melt

In order to melt the resin that has absorbed water, not only the heat energy for melting the resin, but also the heat energy for vaporizing the entrapped water is required. the amount of heat equivalent to the latent heat of vaporization is lost when moistured resin is melted, so extra heating is required.

Glass transition temperature(Tg) decreases

Generally, when the resin absorbs water, the glass transition point decreases. It is considered that water enters the resin, making it easier for the polymer chain to move. Due to the lower glass transition temperature, the softened part of the resin in the hot end becomes wider. This makes 3d prints not sharp.

(3) Hydrolysis

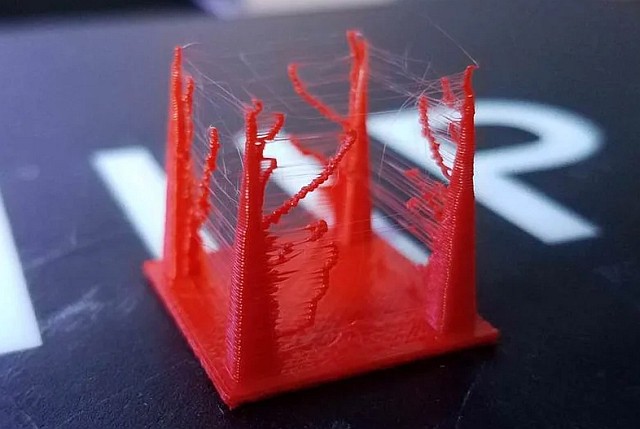

Stringing

Water in resin melt breaks the polymer chain. This hydrolysis causes lower molecular weight and melt viscosity. In simple words, it becomes muddy. Resin drooling from nozzle tend to be stringing when hydrolysis occurs.

3D Print Stringing - Source:all3dp.com

関連ページ

- PLA樹脂のL体とD体について

- ガラス転移点の3Dプリンタ向け解説

- 吸水しにくいフィラメントの選び方

- 結晶性樹脂と非晶性樹脂の違い 3Dプリンタの観点から

- なぜPLAは3Dプリンタで広く使われるのか

- PLA樹脂の歴史と現状

- ABSとはどのような樹脂なのか 3Dプリンタの観点から

- プラスチックの耐熱温度とは何か

- PLAの生分解プラスチックとしての誤解

- PLA表面処理におけるジクロロメタンの危険性

- フィラメントの重さ、長さをWEBで計算

- ホットエンドでフィラメント樹脂もれが起きる理由

- PLAが加水分解すると3Dプリンタでは何が起きるか

- フィラメント交換で3Dプリンタを一時停止させる方法(Simplify3D)

- メルトフラクチャの発生原因と対策

- 世界のPLA(ポリ乳酸)樹脂メーカー

- 樹脂のコンパウンドとは

- PLA樹脂は何に使われている?

- PETG樹脂とは? PETGとPETの違い

- 繊維強化プラスチックの3Dプリント基礎知識

- 2019年に発生したPLA樹脂の世界的需給ひっ迫について

- 樹脂の射出グレードと押出グレードの違い

- PLA樹脂原料の取り扱い、乾燥、再生に関する基礎知識

- 3Dプリンタ ダイレクト式とボーデン式の違いは?

- 3Dプリンタ フィラメントに合ったノズル材質の選び方

- 3Dプリンタのノズル詰まり 考えられる3つのメカニズム

- プラスチックの成形原料「樹脂ペレット」とは?

- PLAの生分解メカニズムについて

- 3Dプリンタ造形中にどんな有害ガスが出るか

- 3Dプリント造形品のアニール処理で何が改善する?

- フィラメントの乾燥で気を付けておきたい3つのこと

- 3Dプリンタで反りはなぜ起こる?(FDM)

- 導電性フィラメントとは?

- PLA樹脂の結晶化 アニール時に起きていること

- FDM式3Dプリンタの分解能の限界はどこにある?

- 造形品の積層強度は結局どうすれば上げられるのか

- なぜこれまで3Dプリンタにはエンクロージャーがなかったのか

- PLA樹脂 2021年の展望

- 3Dプリンタのファーストレイヤーの考え方

- クリーニングフィラメントとは?

- 積層ピッチと造形品強度の関係

- フィラメントはどのように量産している?